after it was subjected to the improvement: Standard

Penetration Test (SPT) and Cone Penetration Test (CPT).

The tests analyzed:

· Liquefaction

· Bearing capacity for the most critical footings

· Settlement analysis for the critical footings

considering the interaction effect of adjacent foundations.

All calculations were in accordance with the

international BS/ASTM standards.

release the pounders, delivering, in a single blow, the energy

equivalent of 1,200 ton/m. The massive impact of the falling

weight triggers a series of actions:

· Immediate densification of granular soils

· Generation of a compression wave that builds pore water

· Generation of high energy shear and surface waves that result in

· Speeding up of the consolidation process.

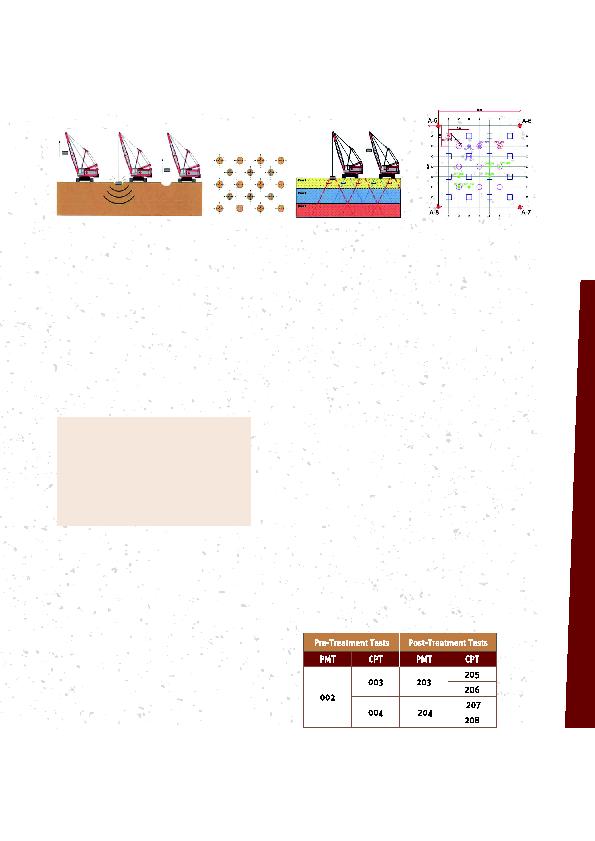

contractor created an onsite calibration area (Figure 3).

The quality control tools selected were the PreTreatment

and PostTreatment Cone Penetration Tests (CPT) and the

Pressuremeter Tests (PMT).

The tests evaluate subsurface conditions from the relative density

point of view, before and after the improvement process. Also,

two Heave and Penetration tests were carried out to determine

the ideal number of blows.

· Number of blows per print

· Drop height

· Type and weight of the pounder

· Number of phases and passes.

turned to a second solution, Dynamic Compaction.

It targets unsaturated and saturated granular

materials, dramatically increases the geotechnical

properties of soil, and has the advantage of

reaching great depths.

with 3035% fines content. It is well adapted

to large areas and results in uniform ground

conditions all over the site. The process of Dynamic

Compaction is illustrated below Figure 2.

for each impact position and in several phases,

following a preset (usually a square grid)

from the surface to intended depth of treatment

tests showed it to be unsuitable for the prevailing

subsurface conditions. This technique was only

able to treat layers up to maximum 2 m in depth.