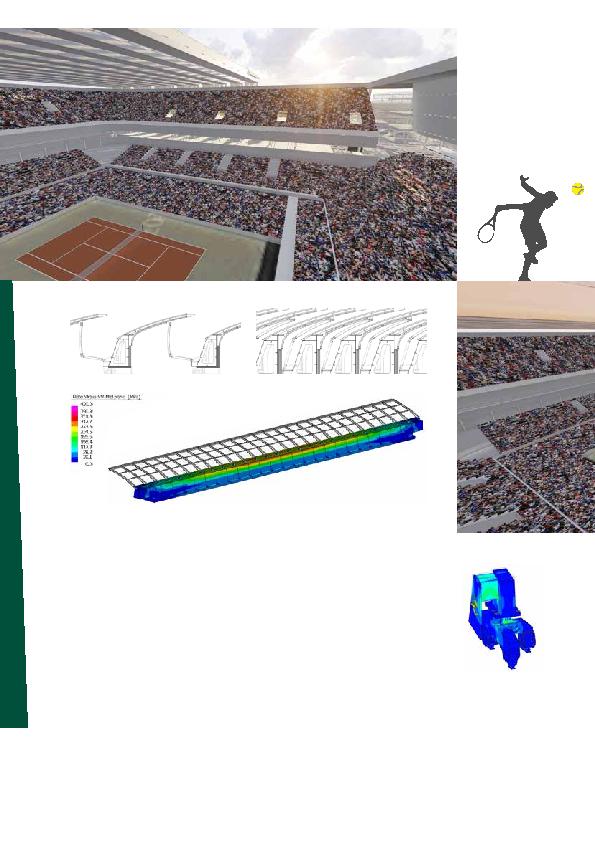

possible by the use of modern ultra-light fabric materials that incorporate wing-like cantilevers, and an

articulated and foldable compass-like system between adjoining beams. The operation of such a retractable

roof is achieved by a custom-designed rack-roller, a truly multi-disciplinary challenge involving both advanced

civil and mechanical engineering skills.

system driven by a pair of gear-motors with two pinions (one for each motor) was selected for each roller. An

electronic differential control system (master-slave) allows the control system to maintain constant and equal

traction. In the case of failure of one of the two motion groups, the pinion can be released and the roller can

move at reduced speed.

Accounting for these important dynamic forces required extensive numerical investigation and wind tunnel

testing of scaled samples under the supervision of Maffeis Engineering.