- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

eyes ahead | i8

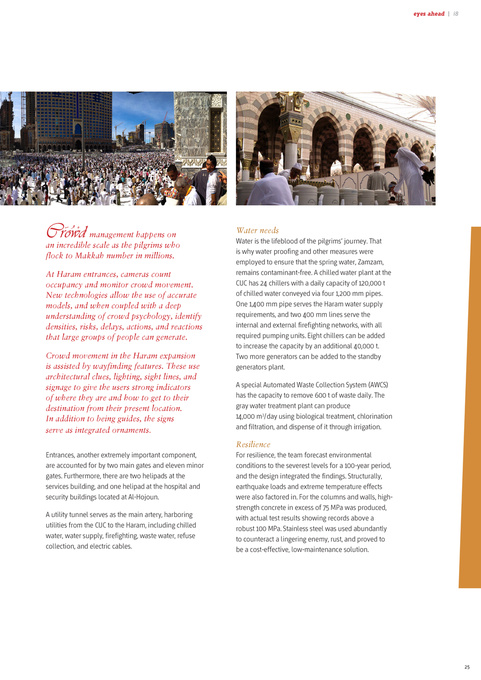

management happens on an incredible scale as the pilgrims who flock to Makkah number in millions. At Haram entrances, cameras count occupancy and monitor crowd movement. New technologies allow the use of accurate models, and when coupled with a deep understanding of crowd psychology, identify densities, risks, delays, actions, and reactions that large groups of people can generate. Crowd movement in the Haram expansion is assisted by wayfinding features. These use architectural clues, lighting, sight lines, and signage to give the users strong indicators of where they are and how to get to their destination from their present location. In addition to being guides, the signs serve as integrated ornaments.

Entrances, another extremely important component, are accounted for by two main gates and eleven minor gates. Furthermore, there are two helipads at the services building, and one helipad at the hospital and security buildings located at Al-Hojoun. A utility tunnel serves as the main artery, harboring utilities from the CUC to the Haram, including chilled water, water supply, firefighting, waste water, refuse collection, and electric cables.

Water needs

Water is the lifeblood of the pilgrims’ journey. That is why water proofing and other measures were employed to ensure that the spring water, Zamzam, remains contaminant-free. A chilled water plant at the CUC has 24 chillers with a daily capacity of 120,000 t of chilled water conveyed via four 1,200 mm pipes. One 1,400 mm pipe serves the Haram water supply requirements, and two 400 mm lines serve the internal and external firefighting networks, with all required pumping units. Eight chillers can be added to increase the capacity by an additional 40,000 t. Two more generators can be added to the standby generators plant. A special Automated Waste Collection System (AWCS) has the capacity to remove 600 t of waste daily. The gray water treatment plant can produce 14,000 m3/day using biological treatment, chlorination and filtration, and dispense of it through irrigation.

Resilience

For resilience, the team forecast environmental conditions to the severest levels for a 100-year period, and the design integrated the findings. Structurally, earthquake loads and extreme temperature effects were also factored in. For the columns and walls, highstrength concrete in excess of 75 MPa was produced, with actual test results showing records above a robust 100 MPa. Stainless steel was used abundantly to counteract a lingering enemy, rust, and proved to be a cost-effective, low-maintenance solution.

25